understanding RHS/CHS/SHS

Introduction of RHS/CHS/SHS: When it comes to structural engineering and construction, choosing the right materials is crucial for ensuring strength, durability, and efficiency. One popular choice for various applications is hollow structural sections (HSS), which come in different shapes and sizes. In this blog post, we will delve into three common types of HSS: RHS (Rectangular Hollow Sections), CHS (Circular Hollow Sections), and SHS (Square Hollow Sections). We’ll explore their characteristics, advantages, and typical uses, shedding light on their importance in modern construction.

- RHS (Rectangular Hollow Sections): RHS refers to rectangular-shaped hollow structural sections. These sections are characterized by their rectangular cross-sections with sharp corners. RHS offers excellent load-bearing capacity and structural stability due to its shape. It is widely used in construction projects requiring beams, columns, frames, and other structural components. The straight edges of RHS make it suitable for joining and connecting with other materials easily. Common applications include building frames, bridges, machinery, and architectural structures.

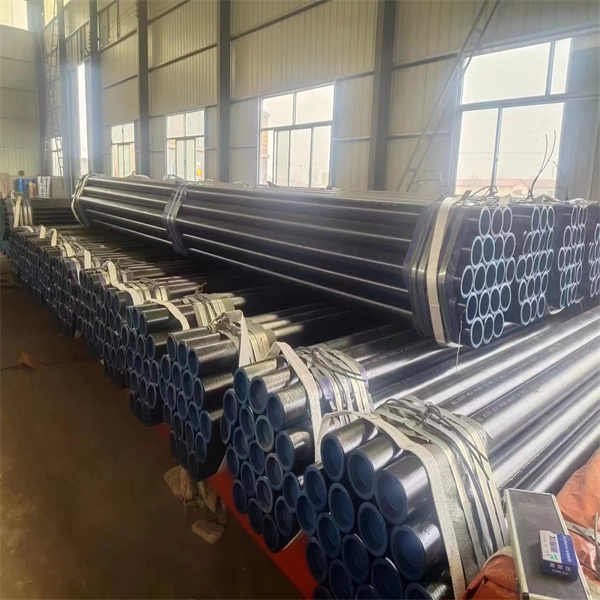

- CHS (Circular Hollow Sections): CHS consists of circular-shaped hollow structural sections, resulting in a uniform and symmetrical appearance. The circular geometry of CHS provides exceptional strength and resistance to bending, making it ideal for applications involving high loads or pressure. Additionally, the absence of corners reduces stress concentrations, enhancing the overall structural integrity. CHS finds extensive use in infrastructure projects such as pipelines, poles, handrails, and automotive components. Its versatility, combined with its aesthetic appeal, makes CHS a popular choice in architectural designs as well.

- SHS (Square Hollow Sections): SHS features square-shaped hollow structural sections, characterized by equal-length sides and right-angled corners. Similar to RHS, SHS provides robustness and stability due to its geometric properties. The equal lengths of the sides facilitate ease of construction and simplify the design process. SHS is commonly employed in applications requiring load-bearing structures, such as frames, columns, braces, and support beams. It is also utilized in furniture manufacturing, fencing, and various architectural elements.

Advantages of HSS:

- High strength-to-weight ratio: HSS offers excellent structural strength while being relatively lightweight, reducing material and transportation costs.

- Aesthetically pleasing: The uniform shapes of RHS, CHS, and SHS contribute to visually appealing designs, making them popular in architectural applications.

- Versatility: HSS can be easily customized, cut, and welded to meet specific project requirements, providing flexibility in design and construction.

- Resistance to corrosion: HSS sections can be manufactured with protective coatings or made from corrosion-resistant materials, ensuring long-term durability in various environments.

Conclusion: Hollow structural sections (RHS, CHS, and SHS) play a vital role in modern construction due to their exceptional strength, versatility, and aesthetic appeal. Whether it’s for load-bearing structures, architectural designs, or infrastructure projects, these HSS options offer unique advantages that make them stand out in the field of structural engineering. Understanding the characteristics and applications of RHS, CHS, and SHS enables engineers and architects to make informed decisions, resulting in safe, efficient, and visually pleasing structures.