An In-Depth Look at ASTM A179 Boiler Tubes-Enhancing Efficiency and Safety

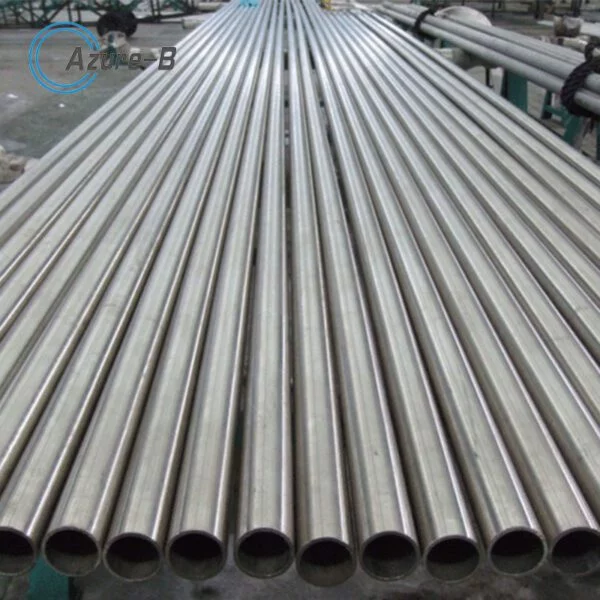

Boiler tubes are a crucial component in steam boilers, acting as the conduit for water and steam transport. The quality and reliability of these tubes have a significant impact on the overall performance and safety of industrial boilers. ASTM A179 is a widely utilized standard that provides specifications and test methods for seamless cold-drawn low-carbon steel boiler tubes for high-pressure service in stationary power plants and industrial facilities.

In this blog post, we will take an in-depth look at ASTM A179 boiler tubes to better understand their critical purpose and technical attributes. We will explore why they are vital for optimizing boiler efficiency and safety, review the key provisions within the ASTM A179 standard, and discuss related specifications and grades. Whether you are a facility manager, engineer, or procurement officer, a stronger comprehension of ASTM A179 can empower smarter materials selection and quality assurance.

Vital Role of Boiler Tubes

Boiler tubes transport high-temperature, high-pressure water and steam from the boiler to the turbines that power generators for electricity production. This intensely hot and pressurized fluid flow necessitates durable tubing that can provide consistent integrity over years of thermal cycling and stress. Boiler tube failures can lead to catastrophic explosions or forced facility outages – both disastrous scenarios.

ASTM A179 tubes are tailored to endure these rigorous service conditions. Their tightly controlled chemical composition and structural properties allow them to resist corrosion, oxidation, and creep damage within boiler fireboxes and flue gas passages. At the same time, their high heat transfer ability maximizes the efficiency of steam generation and electricity output. Keeping these tubes in optimum shape is paramount for safety and profitability.

Overview of ASTM A179 Standard

First issued in 1947, ASTM A179 outlines essential guidelines for low-carbon steel boiler tubes to perform reliably in high-heat installations. It defines permissible carbon levels, inclusion limits, hardness ranges, minimum tensile properties, and mandatory NDE testing. The standard also indicates appropriate processing and heat treatment methods. Compliance with these parameters ensures the tubes resist deformation under prolonged high temperatures while maintaining adequate ductility for manipulation into boiler components.

Several grades are included within the A179 standard:

-Grade A Boiler Tubes: The most affordable option for light-duty service up to 300 psi. Not heat treated.

-Grade C Boiler Tubes: Moderate strength tubes for pressures between 250 psi and 775 psi. Normalize and temper heat treated.

-Other Higher Grades: Increased strength variants for demanding high-pressure, high-heat applications. Quenched and tempered for enhanced properties.

By selecting the appropriate grade for specific pressure and temperature conditions, A179 enables customization of strength, safety margins, and cost-efficiency.

Related Specifications and Compliments

While ASTM A179 regulates baseline chemistry and testing, various complementary standards help create a comprehensive suite of specifications tailored for specialized boiler tube applications:

-ASTM A192: Seamless carbon steel boiler tubes for high pressure service above 775 psi. Also defines firebox quality variants.

-ASTM A210: Specifies minimum carbon, manganese and phosphorus levels and permissible sulfide inclusion dimensions for higher grades than A179.

-ASME SA179: An equivalent boiler tube standard published by the American Society of Mechanical Engineers (ASME).

-ASTM A213: Seamless ferritic and austenitic stainless steel boiler, superheater, and heat exchanger tubes for high-temperature corrosion resistance.

These specifications build on A179 to provide customized materials performance, fabrication protocols, inspection procedures, and data reporting requirements for individual boiler environments. System designers integrate components meeting the appropriate complementary standards alongside ASTM A179 tubes to assemble safe and efficient boiler systems.

Realizing Optimal Value from ASTM A179

In summary, ASTM A179 boiler tubes are meticulously engineered to handle the taxing operating conditions within modern high-efficiency boilers. Their stringent spec compliance enables process reliability and damage resistance that protects capital assets. Facility managers gain the best value by:

-Choosing tube grades capable of withstanding max pressures and temperatures with margin.

-Implementing robust QA practices to validate A179 compliance.

-Following preventive maintenance schedules to maximize service longevity.

Properly leveraging ASTM A179 within a comprehensive systems approach allows power plants and industrial sites to enhance boiler efficiency, safety, and availability over decades of operation. Their strong capabilities continue generating excellent returns on investment.