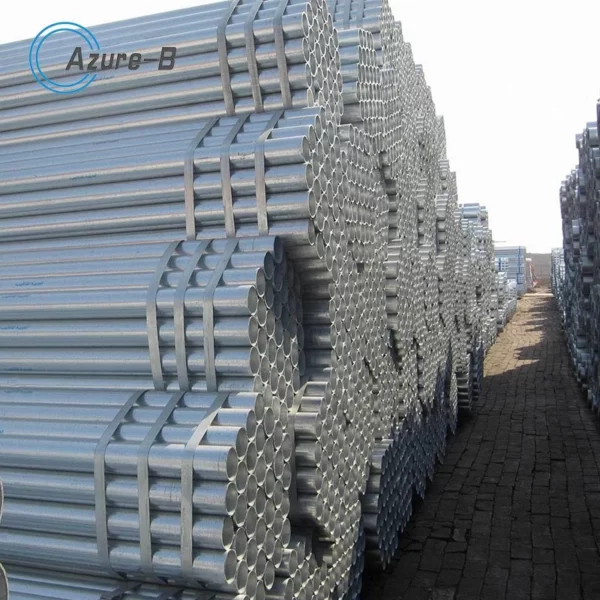

The Strength and Durability of Galvanized Steel Tubing

Galvanized steel tubing offers unmatched strength and longevity across numerous industrial and residential applications. This versatile metal product consists of carbon steel piping coated with a protective zinc layer, making it highly corrosion resistant while retaining excellent structural integrity.

In this comprehensive guide, we’ll explore the key benefits, use cases, manufacturing process, and alternatives to galvanized steel tubing. Read on to discover why it has become an indispensable building block for construction projects both large and small.

Key Benefits of Galvanized Steel Tubing

Galvanized tubing provides a robust yet lightweight tubular solution suitable for factory equipment, trellises, handrails, carports, livestock pens, and much more. Its signature blend of strength, durability, and affordability sets it apart from stainless steel or copper options. Let’s analyze the core advantages galvanized tubing delivers:

Superior Corrosion Resistance

At galvanized tubing’s heart lies steel reinforced by a thick zinc coating applied through a hot-dip galvanizing process. This zinc shield strongly adheres to the steel, acting as a sacrificial anode that actively combats corrosion caused by exposure moisture, chemicals, salt, and other threats. Even if the coating becomes scratched, the zinc around the steel remains intact to prevent oxidation and rust.

High Structural Strength

With zinc only coating the exterior, galvanized tubing retains the full structural strength of steel on the inside. Its robust construction handles high pressure flows in industrial piping applications while also providing sturdy support as structural framework elements in buildings. Pound for pound, galvanized steel demonstrates better stress resistance than wood or aluminum.

Cost-Effective Pricing

Benefitting from abundant steel supply and efficient galvanizing techniques, galvanized steel tubing costs notably less than stainless steel while vastly outperforming aluminum or other metals in durability. This combination of low cost and high performance makes it financially approachable for small DIY projects all the way up to expansive professional construction initiatives. Galvanized tubing offers outstanding value per foot.

Varied Sizing Options

Galvanized steel tubing comes readily available in square, rectangular, and round varieties spanning a wide selection of outside diameter measurements and wall thicknesses. This flexibility empowers users to choose the right tubing shape and strength for the demands of each application, reducing excess weight and material costs.

Low Maintenance Needs

Once installed, galvanized steel requires minimal upkeep compared to other metals vulnerable to corrosion, oxidation, and other degradation over time. Annual inspections help spot any damage to the protective zinc coating, allowing simple touch-ups to maintain performance. This set-it-and-forget-it quality ensures galvanized tubing remains resilient for decades rather than needing frequent replacement.

Common Use Cases for Galvanized Steel Tubing

Thanks to its winning blend of strength, extended durability, and cost-efficiency, galvanized steel tubing tackles a sweeping range of residential, commercial, and industrial applications.

Structural Framework

Serving as underground foundations, vertical columns, or cross-bracing, galvanized tubing withstands immense loads as key structural supports in buildings. Architects favor its high stress tolerance and corrosion resistance.

Protective Railings and Barriers

Galvanized tubing shines as railings for catwalks, equipment cages, perimeter fencing, and more hazardous areas needing stability with see-through visibility. Its durability also suits road barriers, bollards, and parking stops subject to vehicle impact.

Piping and Conduit Runs

In factories and utilities, galvanized piping efficiently transports high-pressure liquids and gases while avoiding corrosion-induced leaks. The same tubing acts as protective conduits shielding electrical wiring across worksites.

Trellises, Pergolas, and Patios

For outdoor secondary structures like overhead trellises, patio covers, carports, and animal enclosures, galvanized steel tubing stands up to intense sun, moisture, soil contact, and temperature swings year after year.

Furniture and Recreation

Lightweight yet load-bearing galvanized tubing enables gym equipment, industrial shelving, portable staging, and utility carts to handle vigorous activity while resisting wear. Galvanized steel also maintains its good looks despite outdoor exposure when used in park benches, bleachers, and picnic tables.

In sighting these examples, it becomes clear galvanized steel tubing rightfully earns a central role across an array of residential, commercial, and industrial settings where longevity and structural integrity hold paramount importance.

Manufacturing Process Behind Galvanized Steel Tubing

Now that we’ve surveyed galvanizing tubing’s inspiring capabilities, let’s delve into the fascinating production process that imparts such resilient properties.

How does plain carbon steel transform into a corrosion-fighting powerhouse? The answer lies in hot-dip galvanizing. During hot-dip galvanizing, manufacturers submerge steel tubing in molten zinc baths reaching temperatures as high as 860°F.

This searing zinc solution initiates a metallurgical reaction bonds the zinc and steel on a molecular level. As the tubing gets pulled from the bath, the zinc evenly coats all surfaces while the steel reaches near molten state, thus preventing future flaking or peeling. The resulting zinc alloy layer measured in mills rather than microns for enhanced longevity compared to other techniques like electrogalvanizing.

After cooling and excess zinc runoff, manufacturers centrifuge the galvanized tubing to remove impurities and smooth any bulges before cutting to desired lengths. Rigorous testing confirms uniform zinc coverage inside and out along with dimensional accuracy and structural integrity. Compared to tube fabrication, injecting galvanizing properties into standard steel piping provides tremendous production efficiencies.

Alternatives to Galvanized Steel Tubing

Despite galvanized steel dominating many construction niches, various specialty scenarios may call for alternative metals. Let’s examine a few of the most common substitutes and how they stack up.

Stainless Steel

Containing chromium and nickel alloys, stainless steel resists corrosion through its inherent molecular qualities rather than a protective coating. It offers aesthetic appeal but costs substantially more while lacking the same structural strength as galvanized steel. Weight also becomes a concern in scaffolding, staging, or overhead installations.

Aluminum

Aluminum delivers extraordinary lightness and ample corrosion resistance outside of marine environments. However, aluminum lacks steel’s high load capacity and pressure durability. Aluminum dent and gauges easier under impact, requiring thickness boosting that then offsets any weight savings. Its lower melting temperature also limits high temperature applications.

Copper

While prized for electrical and plumbing applications, copper proves far too expensive, heavy, and corrosion prone for structural sections relying on tubular supports. Joints and bends also introduce vulnerabilities unless soldering or welding applied.

PVC and CPVC

For chemical storage and waste drainage, tubing alternatives like PVC and CPVC plastic demonstrate chemical resistance outweighing galvanized steel’s options. Yet they falter badly in high heat situations that can release toxic smoke. As structural members, their strength sits well below steel and aluminum. Careful design consideration helps determine ideal material selection in acidic or industrial environments less suited for galvanized steel’s resilience.

As this comparison shows, alternatives exist to galvanized steel tubing in specific situations where chemical compatibility, weight savings, or thermal properties hold the highest priority. But for general durability, safety margins, and cost control, galvanized steel tubing still can’t be beat across countless project types.