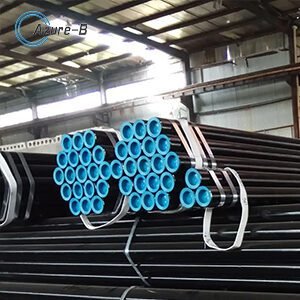

alloy steel pipe supplier

Alloy steel pipes are a crucial component in various industrial applications due to their enhanced properties compared to carbon steel pipes.

Description

Alloy steel pipes are a crucial component in various industrial applications due to their enhanced properties compared to carbon steel pipes. Here’s an overview of their characteristics, uses, and types:

Characteristics

Composition: Alloy steel pipes are made by combining carbon steel with various alloying elements such as chromium, molybdenum, nickel, and vanadium. The specific composition varies depending on the desired properties.

Strength and Durability: The addition of alloying elements generally increases the strength, hardness, and durability of the steel. This makes alloy steel pipes more suitable for high-stress applications.

Corrosion Resistance: Certain types of alloy steel pipes offer improved corrosion resistance, which is critical in environments where exposure to chemicals or corrosive substances is common.

Heat Resistance: Many alloy steels can withstand higher temperatures without losing strength, making them ideal for high-temperature applications.

Common Uses

Oil and Gas Industry: Used for drilling and transporting oil and natural gas due to their strength and corrosion resistance.

Power Plants: Utilized in high-temperature and high-pressure environments found in boilers and steam systems.

Chemical Industry: Employed in chemical processing plants due to their ability to withstand corrosive substances.

Construction and Infrastructure: Used in structures that require strong, durable materials, like bridges and buildings.

Automotive and Aviation Industries: Components in vehicles and aircraft often use alloy steel for its strength-to-weight ratio.

Types of Alloy Steel Pipes

Chromium Alloy Pipes: Ideal for high-temperature service, often used in power plants.

Nickel Alloy Pipes: Known for their excellent corrosion resistance, making them suitable for chemical processing environments.

Chromium-Molybdenum (Chrome-Moly) Pipes: Commonly used in the oil and gas industry, these pipes offer good strength and resistance to heat.

High-Pressure Alloy Steel Pipes: Designed for high-pressure applications, commonly used in power generation and petrochemical industries.

When selecting an alloy steel pipe, it’s essential to consider the specific requirements of your application, including the type of medium it will be exposed to (e.g., corrosive substances, temperatures), the pressures it needs to withstand, and any industry-specific standards or certifications required. Consulting with a knowledgeable supplier or engineer can help ensure you choose the right type of alloy steel pipe for your needs.

- 8 SCH 120 Carbon Steel Pipe

Leave us a message

Related Products

Related Products

- tag -->

- NoDisplayProduct

High-Quality SS400 Steel Pipe: Durable & Versatile for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Steel Pipe Fittings: Durable and Versatile Solutions for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

Premium Stainless Steel Pipe Fittings: Durable & Versatile Solutions

Rated 0 out of 5Read more - NoDisplayProduct

Premium Stainless Tube: Durable & Versatile Tubing Solutions for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

Achieve Superior Quality with ASTM A106: The Ultimate Guide and Benefits

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Carbon Steel Pipe: Durable & Versatile Piping Solution

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality SST Tubing: Durable and Versatile Stainless Steel Tubes

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Stainless Steel Pipes: Durable and Versatile Solutions for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Galvanized Steel Pipe: Durable & Corrosion-Resistant Solutions

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Stainless Steel Tubes: Durable, Versatile, and Affordable

Rated 0 out of 5Read more