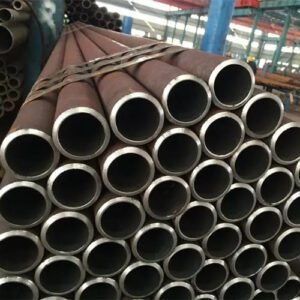

ASTM A106 Seamless Carbon Steel Pipe

| Size | ranging from 1/2 to 28 inches |

|---|---|

| Grades | ASTM A106 grade A,ASTM A106 B and ASTM A106 C |

| Length | single random lenght (17-24') or double random lenght (36 -44') |

| Application | used in the oil & gas, petrochemical, power generation and ship-building industries . |

Description

ASTM A106 Carbon Steel Pipe For High Temperature

ASTM A106 / ASME SA106 pipes are seamless carbon steel pipes used for high tempertaure applications (up to 750 degrees F). These pipes are widely used in the oil & gas, petrochemical, power generation and ship-building industries (examples: refineries, downstream plants, vessels. boilers and towers). A106 pipes are particularly suited whenever the transported fluid has either high temperature or high pressure (or both combined).

ASTM A106 / SA106 pipes are available in size range from 1/2 to 28 inches, and in pipe schedules from 10 to 160. These pipes are supplied either in single random lenght (17-24′) or double random lenght (36 -44′).

In terms of material grades, A106 pipes are manufactured in grade A, B and C. NPS 1-1/2? and below are available in the hot finished or by cold drawn type. Pipes of NPS 2 inch and above are generally are hot rolled manufatured. A106 pipes are produced out of killed steel. The chemical composition and Machanical Property of the three grades of ASTM A106 is shown in the following table:

Chemical composition:

| Chemical composition, % | ||||||||||

| Element | C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| max | max | max | min | max | max | max | max | max | ||

| A106 Grade A | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| A106 Grade B | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| A106 Grade C | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Machanical Property:

| ASTM A106 pipe | Grade A | Grade B | Grade C |

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

Hydrostatic Test of A106 pipes:

The hydrotest shall apply a pressure equal to 60% of the minimum yield strength for at least 5 seconds at atmospheric conditions. The maximum pressure shall not exceed 2500 psi for pipes up to 3 inches, and 2800 for larger sizes. If additional, non standard, tests are executed the pipe shall bear an “S” mark on each lenght or pipe bundle.

Pipe marking:Each length of pipe (or bundle for smaller diameters) shall have the following markings applied:

Material grade(ASTM A106 A / B / C )

Hot Tags: A106 seamless pipe A106 gr.b seamless pipe A106 carbon steel pipe A106 high temperature steel pipe ASTM A106 Grade B Pipe ASTM A106 Grade A Pipe ASTM A106 Grade C Pipe A106 carbon steel seamless pipe

Leave us a message

Related Products

Related Products

- tag -->

- Carbon steel pipe

Seamless Steel Tubes and Pipes for Boilers steel boiler pipe

Rated 0 out of 5Read more