Description

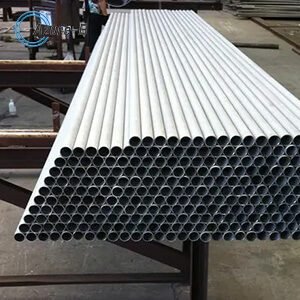

ASTM A312 Stainless Steel Pipe

ASTM A312 is a widely recognized standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipes. These pipes are commonly used in various industries such as chemical processing, oil and gas, food processing, and pharmaceuticals, among others.

With a focus on durability and corrosion resistance, ASTM A312 stainless steel pipes are manufactured using high-quality materials and advanced production techniques. The pipes are made from austenitic stainless steel alloys, which are known for their excellent resistance to corrosion, oxidation, and high temperatures.

The seamless variant of ASTM A312 pipes is produced by piercing a solid cylindrical billet and then rolling it to the desired size and thickness. This seamless construction ensures a uniform and reliable product, free from weld seams that can be potential weak points.

On the other hand, the welded version of ASTM A312 pipes is fabricated by joining the edges of stainless steel plates or strips together using various welding methods. This process results in a robust and durable pipe while maintaining the corrosion resistance of the base material.

ASTM A312 stainless steel pipes are available in a wide range of sizes, schedules, and grades, meeting the diverse needs of different applications. The specified grades include TP304/304L, TP316/316L, TP321, TP347, and more, with each grade offering unique properties suitable for specific environments and mediums.

These pipes exhibit exceptional mechanical properties and have excellent tensile strength, yield strength, and elongation, ensuring their ability to withstand high-pressure conditions and handle various operational stresses.

In summary, ASTM A312 stainless steel pipes stand as a reliable and durable choice for applications that require excellent corrosion resistance and strength. Their adherence to stringent quality

| Table 1 con’t Nominal composition of nickel-containing alloys most are used in sulphuric acid systems | |||||||||

| Nominal composition, % | ASTM Spec. b | ||||||||

| Alloy | UNS numbera | Ni | C | Cr | Mo | Cu | Fe | Plate | Seamless tube and pipe |

| Austenitic stainless steels | |||||||||

| 304 | S30400 | 8 | 0.04 | 18 | – | – | Bal | A240 | A312 |

| 304L | S30403 | 8 | 0.02 | 18 | – | – | Bal | A240 | A312 |

| 316 | S31600 | 10 | 0.04 | 16.5 | 2.1 | – | Bal | A240 | A312 |

| 316L | S31603 | 10 | 0.02 | 16.5 | 2.1 | – | Bal | A240 | A312 |

| CF8M | J92900 | 10 | 0.04 | 19 | 2.3 | – | Bal | – | – |

| 310 | S31000 | 21 | 0.05 | 25 | – | – | Bal | A240 | A312 |

| 20 | N08020 | 33 | 0.02 | 19.5 | 2.2 | 3.2 | Bal | A240 | B729 |

| CN7M | N08007 | 29 | 0.04 | 20 | 2.3 | 3.5 | Bal | – | – |

| 904L | N08904 | 24 | 0.01 | 20 | 4.5 | 1.5 | Bal | A240 | A312 |

| 6%Moc | S31254 | 18 | 0.01 | 20 | 6.2 | 0.7 | Bal | A240 | A312 |

| 6%Moc | N08367 | 24 | 0.01 | 21 | 6.2 | – | Bal | A240 | A312 |

| 6%Moc | N08926 | 25 | 0.01 | 20.5 | 6.2 | 1 | Bal | A240 | A312 |

| 7%Mo | S32654 | 22 | 0.01 | 24 | 7.3 | 0.5 | Bal | A240 | A312 |

This specification covers seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service. ASTM A312 316L properties and ASTM A312 316L chemical composition are listed in the ASTM A312 specification.

OD: NPS 1/8″ to 30″

WT: SCH 5S, 10S, 40S, 80S

Length: 5.8M, 6M, 11.8M, 12M, or any other economical length

Manufacturing Process: Seamless and Welded.

Grade: TP304, TP304L, TP316, TP316L, TP309S, TP310S, TP317, TP317L, TP321, TP347, TP348, 904L

6% Mo (UNS S31254, UNS N08367, UNS N08926), 7% Mo (UNS S32654),

4% Si (UNS S30600), 5% Si (UNS S30601), 5% Si (UNS S32615), 6% Si (UNS S38815)

Leave us a message

Related Products

Related Products

- tag -->

- NoDisplayProduct

High-Quality SS400 Steel Pipe: Durable & Versatile for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Steel Pipe Fittings: Durable and Versatile Solutions for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

Premium Stainless Steel Pipe Fittings: Durable & Versatile Solutions

Rated 0 out of 5Read more - NoDisplayProduct

Premium Stainless Tube: Durable & Versatile Tubing Solutions for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

Achieve Superior Quality with ASTM A106: The Ultimate Guide and Benefits

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Carbon Steel Pipe: Durable & Versatile Piping Solution

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality SST Tubing: Durable and Versatile Stainless Steel Tubes

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Stainless Steel Pipes: Durable and Versatile Solutions for Various Applications

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Galvanized Steel Pipe: Durable & Corrosion-Resistant Solutions

Rated 0 out of 5Read more - NoDisplayProduct

High-Quality Stainless Steel Tubes: Durable, Versatile, and Affordable

Rated 0 out of 5Read more